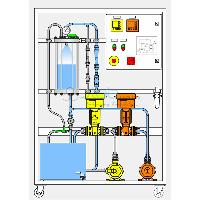

Boiler Heating Batching Process Control System

Product Code : JA-AM-6478

Boiler Heating Batching Process Control System

- This complete and comprehensively equipped laboratory test stand offers numerous possible experiments from the areas of process control.

- It contains a total of four different control loops with local digital, industrial controllers.

- In addition, it is also possible to realise two cascade control systems.

- A further controller is provided for cascade control.

- The controllers can be configured independently of each other as required and can be operated both individually and simultaneously.

- They all have serial interfaces.

- The experimental section is formed by a closed water circuit.

- Water is pumped from a supply tank through a pipe system by a 1.1 kW centrifugal pump.

- A pneumatically actuated control valve included in this circuit makes allows to change the flow rate and thus to control the circuit.

- The level can be controlled in two stainless steel tanks of differing capacity.

- For this purpose, a bypass mounted on the tank feed is controlled by a further pneumatic valve.

- The two tanks can be connected together to change the character of the control loop.

- An electronically adjustable 7.5 kW heater enables to heat the water as part of a temperature control system.

- During overheating, a siren and an alarm lamp will be activated.

- The system water in the circuit can be cooled by a heat exchanger.

- Freshwater from an external water supply is used as the cooling liquid.

- The pressure control system uses external compressed air at one of the two tanks.

- The test stand is built using only industrial standard components to increase its relevance to practice.

- The support made of steel tubes is fitted with laboratory castors and can thus be easily moved around.

- Software for the process visualization and Profibus card are available as an accessory.